Our proven solution

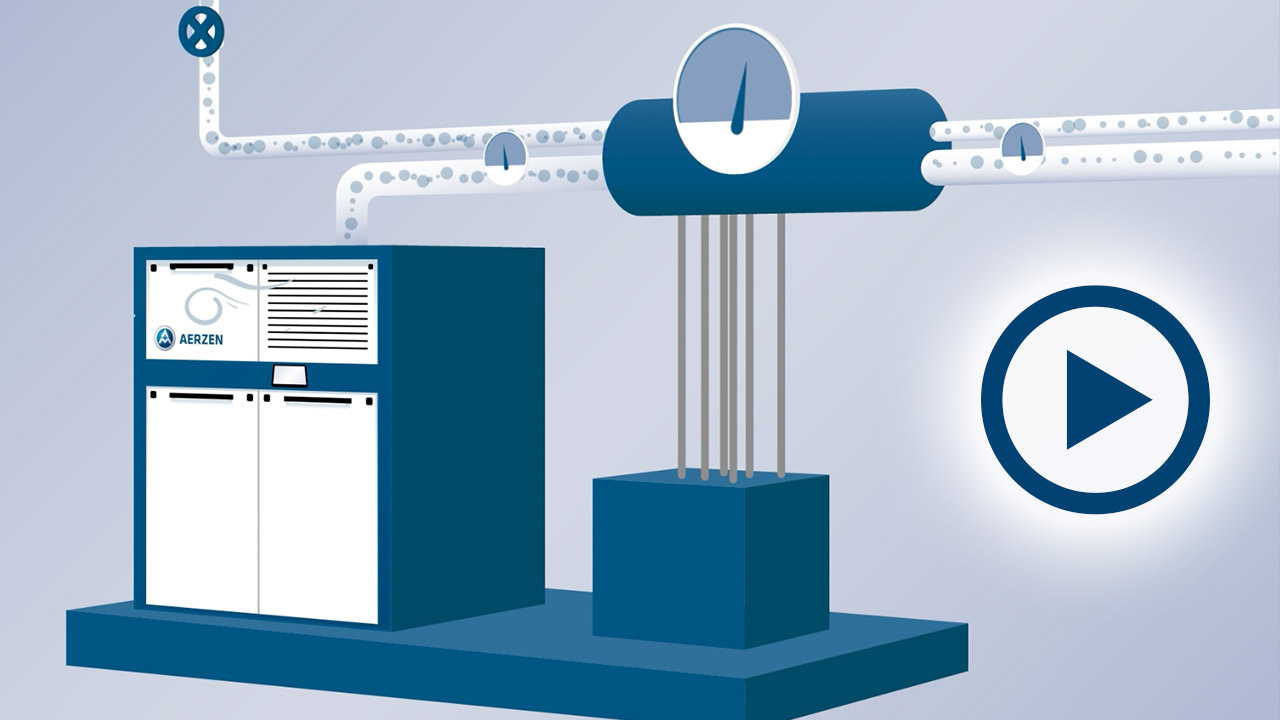

AERprogress offers our customers uncomplicated, direct access to the digital handling of their components.

Affordable,

low-effort offer

Ready-to-use, easily scalable,

stand-alone solution for components

Adding value with new

features

Through the transparent insight into all operating parameters, plant operators can achieve significant additional energy savings, reduce downtime and have an overview of their system at all times and from anywhere.

Ricardo Wehrbein, Managing Director, Aerzen Digital Systems GmbH

AERprogress at a glance

Our IIoT platform has various features and functions that serve to make your system and machines transparent, so that possible errors or potential for optimization can be uncovered better and faster. The platform also supports you in your machine maintenance processes and shows potential anomalies in the operation of the system at an early stage. In addition, you can digitize your process knowledge and make it available centrally in your company for all relevant people.

Did you know that data from the field is usually not used analytically at all and that a lot of potential for optimizing machine availability is lost as a result? Wouldn't it be of interest to be able to have both current process data and historical data from the pressure to the active power over several months and to be able to compare them with one click?

Thanks to the monitoring of all systems by AERprogress, you can always see the condition of your machines and easily understand them over time. Optimum adjustment of availability and utilization to your ongoing operations becomes child's play.

- Digital twin of all machines installed worldwide

- Real-time data as well as historical data over years

- All machine events at a glance

Compressors and blowers can play central roles in chemical or cement plants, for example. If they fail, the system comes to a standstill. The reliability of high-quality systems is already at a high level. However, wear and tear on the machine bearings cannot be prevented. Unexpected machine downtimes resulting from this can cause immense disruption to operations.

Active threshold value monitoring of bearing vibration with AERprogress offers you the opportunity to intervene preventively and to integrate the necessary maintenance process into your operational workflow in an optimized manner. This saves you costs and improves your business continuity.

- Vibration and oscillation values in real time

- Active information when the threshold is exceeded

- Access to all historical sensor data

Who did the last maintenance? What was serviced? Which spare parts were installed? Why was there maintenance at all – out of plan or in coordination with the operating procedure? And when is the next maintenance due?

Thanks to AERprogress, this information and more will be easy for you to understand from anywhere in the future. The digital mapping of all maintenance-related information allows the people involved to see the current maintenance status of their machines at any time. This means that manual inspection and comprehension of individual maintenance logs as well as various consultations with the maintenance engineer are no longer necessary. AERprogress supports you in optimizing your maintenance processes.

- Digital maintenance management

- Full insight into all maintenance documents

- Easier need-based planning of maintenance and servicing

For companies, energy efficiency is more important than ever and represents a competitive factor and an important component for corporate success. In addition to legal obligations, rising energy prices and the need for cost efficiency are also putting pressure on companies to optimize their systems accordingly.

With the help of our energy management, we support you in identifying increased consumption in your systems and in fully exploiting potential savings to optimize energy efficiency and reduce costs by making suitable adjustments to the load profile. It is not just a matter of implementing the legal requirements, rather energy management is an ongoing process that enables you to continuously optimize it.

- Energy consumption of all systems transparently visible

- Reduce costs in the long term through targeted measures

- Increase energy efficiency and conserve resources

Real-time access to all machine data through networking opens up many new possibilities for you - also with regard to error analysis. With AERprogress you not only have all current and past data in view at all times, you can also have yourself and all those involved informed easily and quickly by e-mail about threshold value violations, errors that occur, downtimes or malfunctions.

All events that occur can be viewed transparently in the logbook, can be traced retrospectively and compared with the maintenance and repair measures that have been carried out.

Our logbook and the immediate reporting of your machine's events enable you to have an optimized and efficient process of error analysis and evaluation. The duration of error evaluation is shortened and various communication loops are saved by informing everyone involved. As a result, significant time and cost advantages can be realized.

- Digital and structured documentation of incidents makes error analysis easier

- Digitization of the know-how of specialists and the possibility of self-service

- Realization of cost savings